Long live your skins! Tips for ski touring skin care

Ski skins - they are one of the most important pieces of gear for ski touring, because without them you can’t go uphill. When attached to your skis, the skins prevent you from sliding backward while climbing and at the same time ensure that your ski slides forward well. Sometimes your skins can come off the ski base, snow can clump, the attachment doesn’t stay up, or you slide backwards. In most cases, skins are the guilty party when a tour doesn’t go as planned. Usually when skins don’t perform as they should, it more than likely has to do with incorrect care, user error, transport or drying mistakes. We’ll clue you in to what distinguishes good skin adhesive, and what you can do so your skins last a long time and always work reliably.

Material technology

Premium ski touring skins use either mohair (the hair of the Angora goat) or a mix of mohair and synthetics. Mohair has outstanding gliding and climbing properties and is very light and water resistant. In contrast, synthetics win points with their durability and long lifespan, and they are also significantly less expensive than mohair. Modern skins made from a blendof mohair and synthetics, (such as the DYNAFIT Speedskins) combine these materials in order to utilize the benefits of both worlds. When ski mountaineering racing, mohair skins are almost exclusively used because the focus is all about the absolute best glide to attain the highest speed.

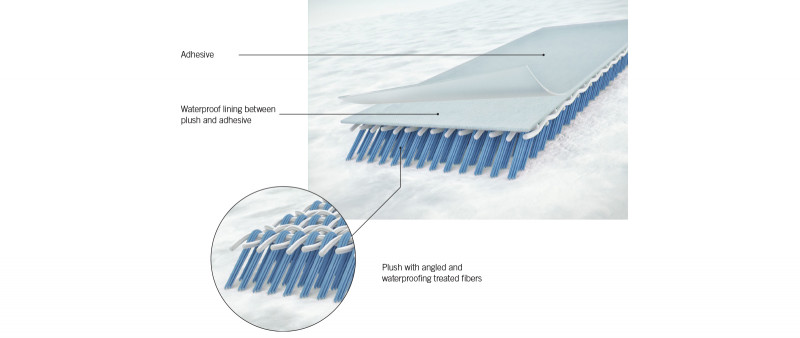

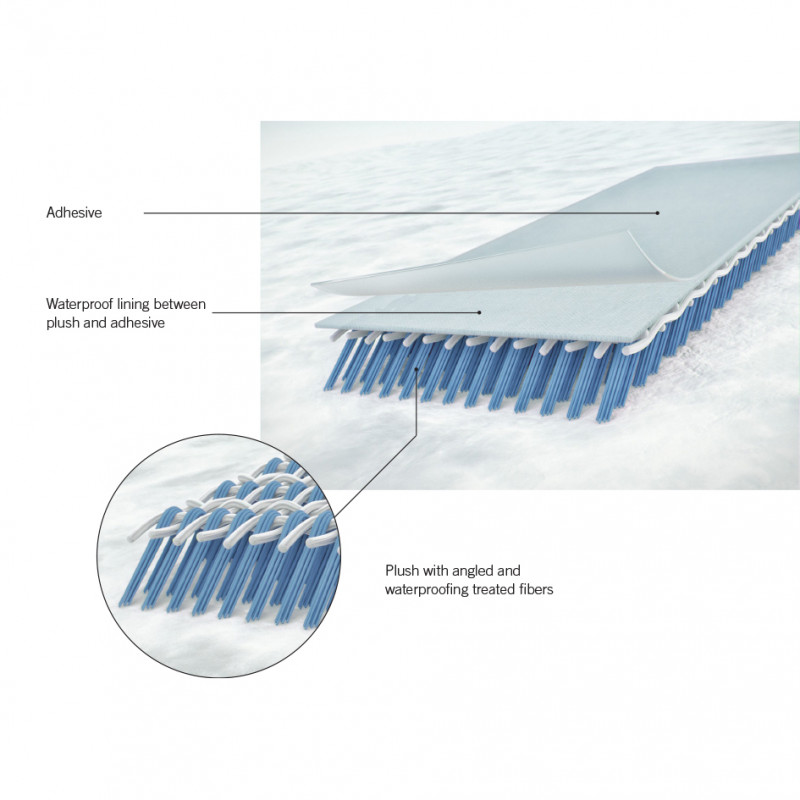

Making ski touring skins – whether mohair or synthetic – is more or less the same. Generally, skins consist of one adhesive layer or undercoat for attaching to the ski base and one “layer” of the actual skin. The actual skin layer is made of a fabric with angled waterproof fibers to give you both gliding and braking direction. DYNAFIT Speedskins, however, feature a particular special feature. In contrast to many others, these skins are built with three layers vs. the traditional two. Between the skin and the base material, there is an additional membrane that has been integrated to keep out water and provide the best grip on the snow.

Always attach skins in the middle of the ski! Steel edges can easily damage skin edges.

Robert Schlemer, product manager, equipment, ski touring

In order for you to maximize the life of your skins, you should always pay attention to; what size you are purchasing, as well as all of the attachment options on your skins - clips, hooks or wires.

When tensioning your skins, know that it doesn’t matter if you start from the tail or the top. If skins are tensioned at the ski tips, then you start attaching them from the tail and then start removing them from the ski tips. If skins are tensioned at the tail, then the process works in reverse.

The skin should in particular cover the width of the ski base well, but in all cases leave the edges free. Most manufacturers offer skins that are already made and delivered to fit a ski, which means you can be sure that the ski and the skins are ideally suited for each other.

Care and handling instructions

Moisture

The most essential step for a long lifespan of ski touring skins is careful handling on a tour. Puddles or very soft snow should be avoided as much as possible. If the skin gets wet, it can lose its waterproofness, which increases the risk of snow clumping later in colder conditions or drier snow. Snow clumping or buildup is perhaps the biggest pain for ski tourers. When snow sticks to skins, you can’t properly glide anymore and forward progress becomes significantly more difficult. This phenomenon primarily occurs when there are big temperature swings on a tour – when the snow at the start is very wet, or skins in some other way become damp. Compared to other skins, DYNAFIT Speedskins have an integrated membrane and water-resistant treatment, which function to inhibit snow clumping or buildup. Whenever you can, avoid moisture as much as possible, and regularly wax your skins or apply waterproof treatments. This will help avoid snow clumps or buildup and at the same time improves the glide and grip properties of skins.

Robert Schlemer

When it comes to the lifespan of skins, taking a short cut through the woods is rarely a very good idea

Proper attachment

Before you attach skins, you should be sure that the base of the ski is clean and dry. Freshly waxed skis should be thoroughly scraped since wax residue can impair adhesive properties. When re-attaching skins during a tour, it is best to wipe the base of the ski dry with a cloth (or, if needed, your jacket sleeve).

DYNAFIT skins should always be separated and stuck directly to each other without the plastic sheets

Robert Schlemer

Proper drying and storage

An important aspect of extending the lifespan of your skins is making sure you dry them properly. After a climb, skins should never be allowed to dry vertically on the skis if temperatures are high or UV rays are intense. Once you are home after a tour, make sure your damp or wet skins dry before you fold them. Never use a heater or other direct source of heat to dry your skins, let them dry at room temperature. Excessive heat or intense sunshine can badly damage the adhesive layer and render the skins unusable. At the end of the season, skins should be stored in their skin bag and kept in a clean, cool, dark place that is not highly moist or dry.

The the basic rule when it comes to the care of ski skins is – “Prevention is better than repairs.” To recap what we have mentioned in this article, be sure that,

1. Wet spots and dirt are to be avoided as much as possible and both the adhesive and skin sides should be treated with care.

2. At very low temperatures carry your skins next to your body.

3. After every tour, dry the skins and never place them on a heater for that.

4. Always carry and store DYNAFIT Speedskins glue-to-glue. They will reactivate when you pull them apart.

5. Regular waxing improves glide and counteracts snow clumping and buildup.

Skin side care

When skins do get dirty, clean them with a damp cloth but do not use any cleaning agents. When frayed edges are present, they can be carefully trimmed with a nail scissor. In doing so, never damage the adhesive side but really only trim the threads.

Moisture is the biggest enemy of ski skins. Preferably just carry skins one extra time than be annoyed the entire tour with the buildup of snow clumps

Robert Schlemer

Adhesive Side Care

When on a tour, not only can the skin side can fail, but the adhesive side can as well. If it is damaged then the skins will become detached from the ski base and snow can be pushed between the skin and skis. When transitioning, pay attention that the adhesive doesn’t touch dirt, pebbles, pine needles or grass, and that skins are protected from heat or UV rays. If the adhesive side still gets dirty, you should try to clean it as well as possible - best to do with a small tweezer or a sharp knife. If you can’t fix the problem and the skins are otherwise in good shape, then the adhesive layer can be restored. To do this, we highly suggest visiting your local specialty retailer/competence center.

Ski skins don’t have any business on a heater! This is a mistake you see over and over again

Robert Schlemer

Life hacks for your tour

Despite fastidious care and the observation of all tips, large and small mishaps can still happen during a tour. It never hurts to have at least one person in the group carrying a few emergency aids to fix a “broken skin.

The most frequent problem that happen on tours with skins is most certainly the glide ability of skins or snow clumping. To counter this, having skin wax or waterproofing spray in a pack can come in handy. If skins are not sticking properly to a ski anymore, you can’t of course restore adhesive when you are out and about, but you can use tape to find some temporary help. Same holds true for the attachment system. If this is defective, you can at least temporarily use tape or zip ties as a solution until you are back in the valley and can find a proper repair.

In sum

Purchasing advice

Once you have found the correct skin for you, then it comes down to the care of them. Every ski touring enthusiast needs to understand that consumable goods and will wear out over time. If you care for your skins well, they will work for you for a long time. If premium quality skins are treated properly, they can last for at least 150,000 meters of vert, often times it can be significantly longer.

Dirt

Aside from moisture, one should also try to protect skins as best possible from dirt, grime, pebbles, resin and roots – which can damage skins badly on both the skin and the adhesive sides. If possible, removal of your skins should happen on clean snow to avoid any debris getting caught in the adhesive. Removing pine needles or grass from the glue is a very tedious job that every ski touring enthusiast would certainly rather avoid.

Proper storage during descent

During a descent, skins must be stored in a clean, dry and somewhat warm place. DYNAFIT Speedskins should be folded in half with the adhesive sides together, so that when the skins are pulled apart, the adhesive is reactivated so you don’t need any extra plastic sheets for DYNAFIT skins. When the temperatures fall below -2°C, skins should be carried close to your body under your jacket or vest to keep them warm. The same holds true on a descent prior to another climb. When adhesive skins are kept safe at a particular temperature, they are much easier to attach.

Video-Tutorial: Skins

Want a refresher on how to best put on and take off skins on a ski tour, check out this short video with Schorsch Nikaes, DYNAFIT Product Director and Mountain Guide: